一、定位油管密封总成

定位油管密封总成是配有密封筒的封隔器的最基本的密封方式。定位密封总成随生产管柱下入井中, 利用自身的止动台肩实现在封隔器顶部的定位。它可以同时实现一组或多组密封

坐封生产封在封隔器密封筒中的定位,建立起封隔器和油管之间的密封。

定位油管密封总成坐入封隔器后,油管通常处于压缩状态,以补偿作业过 程中导致的油管变形。但是,有时不可能也没有必要提供足够的下压重量,特别是在深斜井中。这种情况下,要利用密封延伸筒及其他元件来增加封隔器密封筒的长度。

二、锚定油管密封总成

锚定油管密封总成随着生产管柱下入,下放定位后,锚定卡瓦上螺旋牙扣入封隔器顶部对应螺纹牙, 扣入后锚定和油管就会定位。任何油管收缩引起拉力载荷会作用在管柱上, 使用锚定密封总成时,必须小心确保不会使油管拉断,右旋10到12圈即可松开与封隔器的锚定。

PACK-OFF ASSEMBLY

INTRODUCTION

1. Locator Tubing Seal Assembly

Locator Tubing Seal Assembly is the most basic sealing method of sealbore packers. It is run in the wellbore with production string. Its “locator” is set on the top of the packer, which is achieved by no-go shoulder itself. The locator of sealbore packer can be achieved by one or multi group seals, which make up the seal between packer and tubing. Tubing is ordinarily in the state of compress after locator tubing seal is set on the packer, which can compensate for the tubing distortion, but it is impossible and not necessary to provide enough downward weight, especially in deep deviated well. Under this condition, it is needed to increase the length of seal bore packer by using the seal bore extension.

2. Tubing Anchor Seal Assembly

Tubing Anchor Seal Assembly is run into the well with the production string. While locating , the anchor’s threaded latch is engaged into the thread correspondingly at the top of the packer. Once engaged, the anchor and tubing are securely locked in place. Any tubing contraction will cause a tensile load which applied to the tubing string. Ensure tensile forces development, which do not snap the tubing whenever Tubing Anchor Seal Assembly is used. To release the anchor, it must be rotated by right -hand 10 to 12 turns.

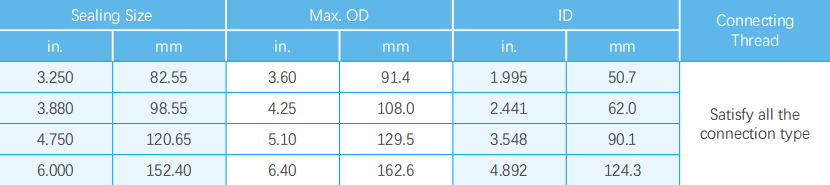

Note: Other specification products are available.