CS-SPR油管回收井下安全阀为阀瓣式、安装于油管上的地面控制的井下安全阀,采 用了平衡阀瓣总成设计,具有自平衡功能。CS-SPR型油管回收井下安全阀由一根小直径 的液控管线连接到地面的应急关断系统并在地面进行控制。此种安全阀为常关阀,当控制 管线的压力泄掉后,安全阀阀恢复到关闭状态,从而关闭油井。 CS-SPR型安全阀将永久锁开功能作为标准配置,不论何种原因导致安全阀不能打开 时,可以下入锁开工具使安全阀处于永久打开的状态。安全阀打开后可将其从井中取出, 或者下入次口径钢丝安全阀于CS-SPR型安全阀的坐挂台肩,钢丝安全阀可利用原来的控 制管线压力,这种情况下,需用打孔工具在CS-SPR安全阀的压力腔打孔,使压力腔的压 力能够传递给钢丝安全阀。 CS-SPR型安全阀带有坐挂台肩和密封光桶。坐挂台肩类型可根据客户需求提供。

主要特性

◎ 安全阀处于关闭状态时,100%金属对金属密封系统;

◎ 非弹性活塞密封系统,耐温耐压高达7500psi和350℉;

◎ 避免钢丝工具损坏的阀板设计;

◎ 带密封光筒和锁开机构,可配合工具使得安全阀处于永久锁开状态及下入次口径安全阀;

◎ 可靠的自平衡系统;

◎ 严格按照API及ISO标准设计制造。

CS-SAPPHIRE (SPR) SERIES SUBSURFACE SAFETY VALVE

INTRODUCTION

Various kinds of new technology are applied in CS-SAPPHIRE series surface controlled subsurface safety valves and perform very well in field applications, reducing significantly common safety valve failures. CS-SAPPHIRE series surface controlled subsurface safety valve is with flapper structure to protect wireline from damages, non-elastomeric sealing technology and metal-to-metal sealing and containment of wellbore fluids when the valve is in the closed position. 25% safety valve failures are due to wireline damages in workover operation. CS-SAPPHIRE series surface controlled subsurface safety valves involve the flapper design for protection of wireline from damages and this design is so successful that it can virtually eliminate such failure mode. This design ensures all seal surfaces are protected from wireline contact even during accidental closure of the valve during wireline operations. CS-SAPPHIRE series surface controlled subsurface safety valves can be customized according to specific needs, with available options such as integral chemical injection capability, wireline damage resistant seal bores, and various control system stop seal versions.

FEATURES

◎ Self-equalizing function of flapper;

◎ Non-elastomeric dynamic seal assembly;

◎ Wireline damage resistant flapper - design protects sealing integrity during wireline operations;

◎ Metal-to-metal seal technology -100% metal-to-metal sealing and containment of wellbore fluids when the valve is in the closed position;

◎ Optional chemical injection capability-injection mandrel within the TRSV eliminates the need for a mandrel above the valve and allows injection of fluids directly into spring cavity for maximum effectiveness.

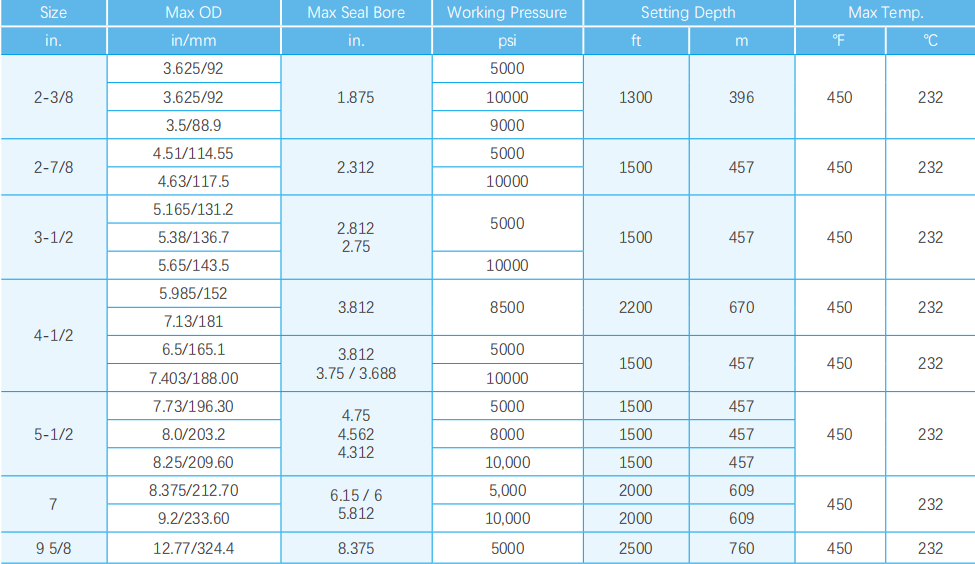

Note: Other specification products are available.