砾石充填防砂完井工艺是针对产能丰富地层同时地层疏松易出砂油井,在完井初期就进行砾石充填作业,筛管与套管(射孔)井壁之间用充填砾石填实,形成连续稳定的高强度砂体,阻止地层砂向井筒运移,从而解决出砂问题。

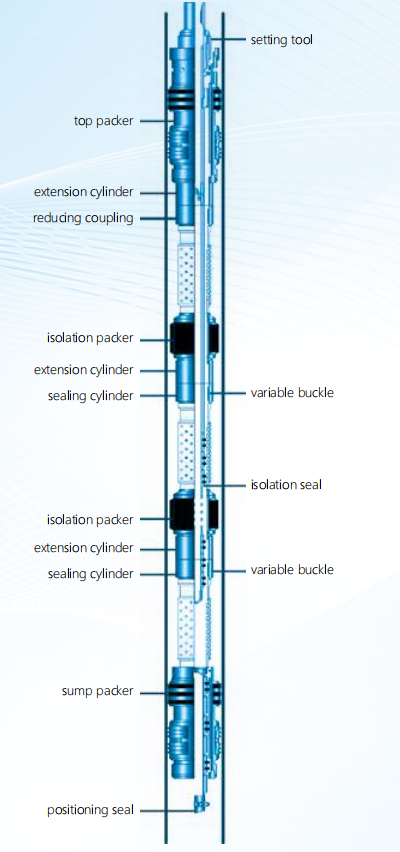

一次多层砾石充填防砂工艺针对套管内同时射开多层的油气井,且每层均需要充填防砂完井。该工艺可一次下入多层防砂工具及服务工具,逐层坐封、充填,层与层之间由隔离密封和隔离封隔器隔离保证充填液不会串层。可实现一次管柱下入完成多层不等距产层的砾石充填防砂作业,大大缩短完井时间。

◎ 可实现单井多层一趟管柱完成封隔器坐封和各层分别充填作业,提高作业效率;

◎ 一趟管柱下入多层防砂工具及服务工具;

◎ 定位工具定位充填位置,防止管柱充填时移位;

◎ 任何一层充填时与其他层隔离,防止完井液漏失;

◎ 每一层充填后可进行验充填,若充填效果不好可再次充填。

SAND CONTROL SYSTEM WITH MULTILAYER GRAVEL PACK FOR HOT - RECOVERY CASING WELLS

Gravel packing sand control completion process is aimed at productive formation and loose formation and easy sand production well.

Gravel packing operation is carried out at the early stage of completion. Gravel packing is used between screen tube and casing (perforation) shaft wall to fill it, forming a continuous and stable high strength sand body, preventing formation sand from migrating to the wellbore, thus solving the problem of sand production.

A single multilayer gravel pack sand control process is designed to fire multiple oil and gas Wells simultaneously inside the casing, and each layer needs to be filled with sand control completion.In this process, multi-layer sand control tools and service tools can be inserted at one time to set and fill layer by layer. The isolation seal and isolation packer can ensure that the filling fluid will not cross layers.It can realize the gravel pack sand control operation of multiple uneven pay zones under a single string, greatly reducing the completion time.

◎ Tthe packer setting and filling of each layer can be completed in a single well with multiple layers and a single string, so as to improve operating efficiency;

◎ multi-layer sand control tools and service tools are inserted into the pipe string in one trip;

◎ positioning tool locates the filling position to prevent the displacement of the pipe string during filling;

◎ any filling layer shall be isolated from other layers to prevent completion fluid leakage;

◎ after filling each layer, the filling can be tested. If the filling effect is not good, the filling can be repeated.